Made in Maryland is a monthly segment by ABC 2's Cassie Carlisle, showcasing local unsung trades. If you know a company fitting this description email Cassie.Carlisle@wmar.com.

A business built on carbs, now survives on quite a different diet.

Marlin Steel was founded in 1968, by a man with modest means, who learned the trade from his father-in-law.

"For 30 years we were making bagel baskets for the entire world," President and Current Owner Drew Greenblatt said.

Greenblatt bought the business in 1998.

He persuaded nine employees to move with the business to Baltimore by chauffeuring them and their families to the new factory in a limo-bus, providing realtors who showed them the residential community and hosting a lunch.

At the time Greenblatt knew nothing about manufacturing, but he was a successful entrepreneur.

"I always wanted to be an entrepreneur. I find it challenging, everyday it's new topics, new things to tackle," Greenblatt said.

He succeeded before, buying a burglar alarm company and selling it for a profit. Marlin Steel, on the other hand, gave him quite a challenge.

They don't own a tape measure, a bagel retail shop. So, what they consider good is if the bagel doesn't fall out that's a success." -Drew Greenblatt, President Marlin Steel

Notes on dimensions were taken the old-fashioned way, written down in a small book.

The times caught up though, China took most of their business, selling bagel basket less than the price of steel required to make it. At the same time, the Atkins diet became widely popular, sending bagel stores into bankruptcy.

Then, the future called, and on the other end of the line: Boeing.

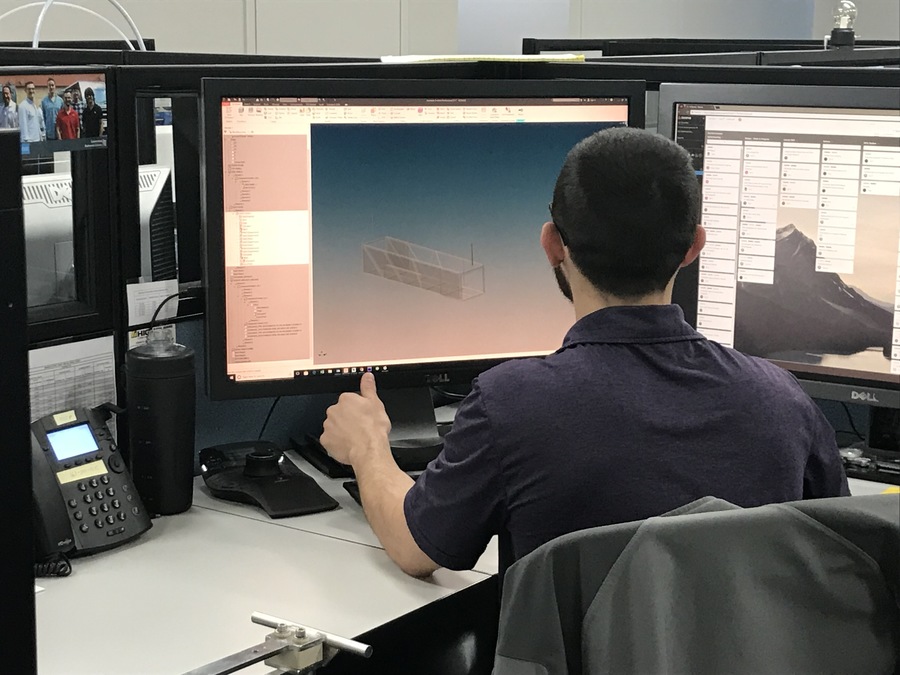

"[A Boeing engineer] Needed a customized basket and we jumped on it and we made it for him. We realized this is our future, focusing in on engineering products, highly engineered, high quality, fast delivery," Greenblatt said.

The transition didn't come without hiccups. Failed prototypes, purchases of new expensive equipment, and new stringent procedures added to the workflow were just a few things Greenblatt did to measure up to the engineering company's incredibly high standards.

"Our baskets are used in the factories because they're used to go down the conveyor belts and robots pick them up and they move parts and put parts inside it and our baskets go into ovens, they go into acid baths," Greenblatt said.

The baskets are now sold to companies like Toyota, Ford, General Motors, or Merck.

While he's proud the company's grown eightfold under his management, he can't measure the gratification of seeing his team prosper.

"When I first bought the company it was $8/hour, he walked to work, no health insurance plan, you know his health insurance plan was to go to the emergency room," Greenblatt said about his most seasoned employee, Hector Carmona.

Carmona came to the U.S. when he was 22, and found a job at Marlin Steel through a friend.

He's worked for the company ever since.

"Now he owns a home. Him and his spouse own a car, his family is on the same health insurance plan my family is on and he's going to make about 60 large this year," Greenblatt said.

Carmona said this job has helped him finance a college education for both his adult children.

I believe manufacturing is the best way to pull people from poverty into the middle class. I think manufacturing is the key to Baltimore City," Greenblatt said.

Unlocking opportunity for those reaching for the door.

"People are real, and you can really build a business in Baltimore, so I'm a huge backer of Baltimore, I love Baltimore," he said.

A love manufactured for 50 years in Maryland.

Fun Fact: The sculpture hanging in front of their South Baltimore factory was made by local students. The original owner named the business after his love of deep sea fishing.